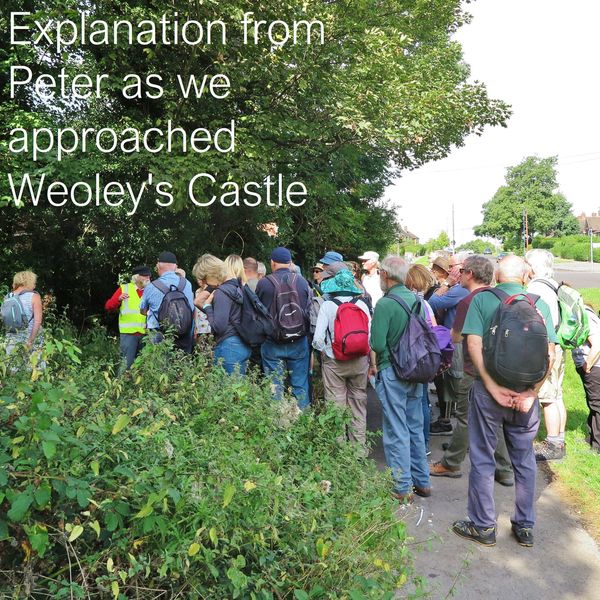

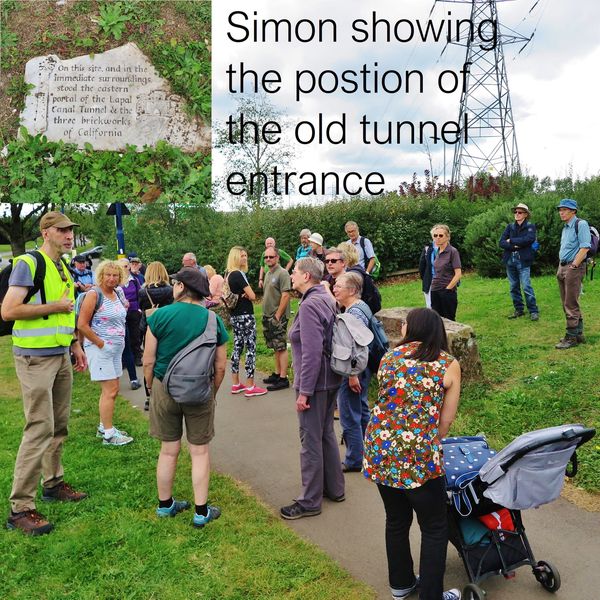

Walk the Line 2021. Almost 50 walkers, a record, enjoyed a beautiful day for our annual walk along the route of the canal from Selly Oak to the Leasowes in Halesowen. Big thanks to all the walkers and for their interest in restoring the Dudley No 2 Canal. Special thanks to our guides Peter and Simon and to Helen and Jill for providing tea/coffee and cakes/biscuits at the journeys end. Thanks also for the donations amounting to over £110. If you would like to follow this route, look in our The Canal, Discover the Canal for more details.

DAY 3 Good progress with the tree roots removed from both sites, started to pour the concrete for the wall. Had to contend with a wasp nest. In the evening Lapal Canal Trust was pleased to host a dinner in town and a trip by boat. Thanks to Cathy and Dave and nb Bosworth Lady. Last post seen by over 13,400

DAY 3 Good progress with the tree roots removed from both sites, started to pour the concrete for the wall. Had to contend with a wasp nest. In the evening Lapal Canal Trust was pleased to host a dinner in town and a trip by boat. Thanks to Cathy and Dave and nb Bosworth Lady. Last post seen by over 13,400